Exploring the Benefits of Cross-Linked Polyethylene Foam

Cross-linked polyethylene foam offers a plethora of benefits that cater to various industries, making it a sought-after material in the market. Its unique properties set it apart from traditional foam materials, providing unmatched durability, resilience, and thermal insulation. The closed-cell structure of cross-linked polyethylene foam renders it impervious to water, chemicals, and UV radiation, ensuring longevity and reliability in diverse applications.

When it comes to applications, cross-linked polyethylene foam proves to be a versatile solution for a wide range of uses. Whether it’s safeguarding delicate items during transportation through packaging, providing insulation in construction projects, enhancing safety in sports equipment, or ensuring comfort in automotive components, this foam material excels. Its lightweight nature, combined with exceptional shock-absorbing capabilities, makes it a top choice for manufacturers across industries.

The manufacturing process of cross-linked polyethylene foam involves intricate steps that contribute to its superior quality and performance. Through a chemical cross-linking process, the foam’s physical attributes are enhanced, resulting in a robust material with consistent properties. Techniques such as extrusion and cross-linking play a crucial role in shaping the foam’s structure, ensuring that it meets the desired specifications for each application.

One of the standout features of cross-linked polyethylene foam is its environmental sustainability. Being recyclable and free of harmful CFCs, this foam material aligns with eco-friendly practices in manufacturing. Additionally, its energy-efficient production process minimizes environmental impact while its long lifespan and reusability promote sustainable usage. By choosing cross-linked polyethylene foam, industries can prioritize both performance and environmental responsibility.

Unique Properties of Cross-Linked Polyethylene Foam

Cross-linked polyethylene foam stands out for its remarkable properties that set it apart from other materials in the market. One of its key features is its exceptional durability, which ensures longevity and reliability in various applications. The foam’s ability to maintain its shape and structure under pressure makes it a go-to choice for industries requiring robust materials.

Moreover, cross-linked polyethylene foam boasts impressive resilience, allowing it to withstand repeated impacts without losing its cushioning properties. This makes it an ideal material for protective packaging, sports gear, and automotive components where shock absorption is crucial. The foam’s resilience ensures that it can endure rigorous use without compromising on performance.

Another noteworthy property of cross-linked polyethylene foam is its excellent thermal insulation capabilities. The closed-cell structure of the foam creates a barrier that effectively traps heat, making it suitable for applications where temperature control is essential. Whether used for insulating HVAC systems or temperature-sensitive products, the foam excels in maintaining desired thermal conditions.

Furthermore, the closed-cell structure of cross-linked polyethylene foam contributes to its resistance against water, chemicals, and UV radiation. This inherent protection makes the foam versatile and reliable in challenging environments where exposure to harsh elements is a concern. Industries seeking materials that can withstand diverse conditions often turn to cross-linked polyethylene foam for its superior resistance properties.

Applications of Cross-Linked Polyethylene Foam

When it comes to the versatile applications of cross-linked polyethylene foam, the possibilities are truly endless. This remarkable material is widely utilized across various industries for its exceptional properties that cater to a diverse range of needs. Let’s dive into some of the key applications where cross-linked polyethylene foam shines:

- Packaging: Cross-linked polyethylene foam is a popular choice for packaging fragile items due to its cushioning and shock-absorbing capabilities. Whether it’s delicate electronics or valuable artwork, this foam provides reliable protection during transportation.

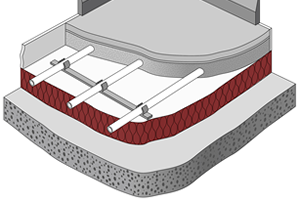

- Insulation: The thermal insulation properties of cross-linked polyethylene foam make it an excellent choice for insulating buildings, HVAC systems, and refrigeration units. Its closed-cell structure effectively traps air, providing energy efficiency and temperature control.

- Sports Equipment: From padding in helmets and knee pads to flotation devices and yoga mats, cross-linked polyethylene foam is a go-to material in the sports industry. Its lightweight nature and impact resistance enhance safety and performance.

- Automotive Components: In the automotive sector, cross-linked polyethylene foam is used in various components such as gaskets, seals, and interior trim. Its durability, resistance to chemicals, and noise absorption qualities make it a reliable choice for automotive applications.

Moreover, the versatility of cross-linked polyethylene foam extends to areas such as medical devices, marine products, and construction materials. Its ability to be easily customized, molded, and fabricated to meet specific requirements makes it a sought-after material in a wide range of industries. Whether it’s providing cushioning, insulation, or protection, this foam proves to be a valuable asset in countless applications.

Manufacturing Process of Cross-Linked Polyethylene Foam

The manufacturing process of cross-linked polyethylene foam involves a series of intricate steps that result in the creation of a versatile and durable material. One of the primary methods used in producing this foam is through a chemical cross-linking process, which enhances its physical properties and overall performance.

During the manufacturing process, raw polyethylene resin is first mixed with various additives to achieve the desired characteristics of the foam. These additives may include colorants, UV stabilizers, flame retardants, and blowing agents, among others. The precise combination of these components is crucial in determining the final properties of the foam.

Once the resin is prepared, it undergoes extrusion, a process where the material is melted and formed into a continuous shape. This extruded material is then cross-linked using methods such as electron beam irradiation or chemical cross-linking agents. Cross-linking is essential as it creates a three-dimensional network within the foam, improving its strength and durability.

After the cross-linking process, the foam is cooled and shaped into the desired form through cutting, molding, or laminating. This step allows manufacturers to create custom shapes and sizes according to specific industry requirements. The final product is then inspected for quality control to ensure it meets the necessary standards.

Overall, the manufacturing process of cross-linked polyethylene foam is a precise and controlled operation that requires expertise and attention to detail. By carefully following each step, manufacturers can produce high-quality foam with exceptional properties suitable for a wide range of applications.

Environmental Advantages of Cross-Linked Polyethylene Foam

Cross-linked polyethylene foam offers significant environmental advantages that contribute to sustainable practices in various industries. Let’s delve into the eco-friendly nature of this versatile material and explore how it aligns with the principles of environmental responsibility.

One of the key environmental benefits of cross-linked polyethylene foam is its recyclability. This foam can be easily recycled and repurposed, reducing the amount of waste that ends up in landfills. By promoting a circular economy where materials are reused, cross-linked polyethylene foam helps minimize environmental impact and conserve resources.

Moreover, the manufacturing process of cross-linked polyethylene foam is energy-efficient. The production of this foam requires less energy compared to other materials, leading to lower carbon emissions and reduced energy consumption. By choosing cross-linked polyethylene foam, industries can lower their environmental footprint and contribute to energy conservation efforts.

Another advantage of cross-linked polyethylene foam is its composition free of harmful chlorofluorocarbons (CFCs). CFCs are ozone-depleting substances that have a detrimental impact on the environment. By using CFC-free materials like cross-linked polyethylene foam, businesses can support ozone layer protection and reduce their contribution to global environmental challenges.

Furthermore, the long lifespan and reusability of cross-linked polyethylene foam make it a sustainable choice for various applications. This foam can withstand multiple uses and retain its properties over time, reducing the need for frequent replacements. By investing in durable and reusable materials like cross-linked polyethylene foam, industries can minimize waste generation and promote a more sustainable production cycle.

As we end our article, do not forget to review Durfoam‘s pe foam, physically cross linked polyethylene foam, chemically cross linked polyethylene foam pages.